Brainstorm!: Provide at least four of your team’s brainstorming ideas for the design solution. This should include brainstorming sketches. Each sketch should include labels and descriptions for communication.

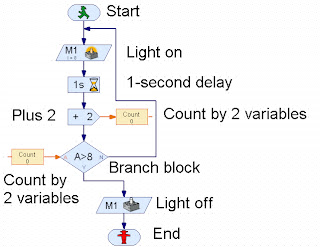

MACHINE 1

MACHINE 2

MACHINE 3

MACHINE 4

Enter the Matrix: Evaluate your solution ideas (4 minimum) using a decision matrix. Determine the best solution to the problem. Explain your rating system and share insight on why you rated your solutions as you did.

Design Solution( Machine 3 design): Create a detailed pictorial sketch or use 3D modeling software to document the best solution, based upon your team’s decision matrix. Your sketch or 3D model should include a rationale for the design selected as the final design solution. Each sketch should include labels and descriptions for communication.

"I've Made a Few Special Modifications...": Document modifications made to your design during implementation. Explain the reason for the modifications and describe how the new design solution will solve the problem. "Story" is the split between expectation and outcome. Tell us a story regarding what your plan was and how it actually came out! Use photos and sketches to call out three changes. (Nerd points if you know where the quote for this Achievement title comes from)

One of our main modifications was puting magnets at the end of the ramp in order to get the metal marble with the magnet instead of the color sensor. This allowed us to use light to sort wood as metal and wood both let 0 light by.

(Han Solo.)

Final Implementation - Video!: Embed a video that showcases your solution in action!

Reflection: Adress the four feedback types that we use in our courses (+, -, ?, !). Solicit feedback from someone outside of your team as well.

Some questions to consider in this section: How well did you accomplish your objectives? What would your team do differently with your design solution and why? Do the results fulfill the problem statement? Provide a brief explanation of what you learned, the challenges of working in a design team, and the purpose of the design problem.

+: It is compact, and we probably used the least amount of parts. It has a simple design.

- : might take a long time to sort, needs to much programing.

? : Could making it bigger make it easier, could using pistons be easier than motors.

! : Make it bigger!!, use pistons for the sorting(faster).

Reference: Post a hotlink to material you referenced on the internet. Explain why this information is significant to your project.

Product Achievements:

Marble Sorting (some achievments scored multiple times):

Sort one marble (x1)

Sort two marbles (x1)

Sort three marbles (x1)

Sort four marbles (x1)

Marble Delivery (may use non-fischertechnik materials to create a "hopper" to drop marbles into for "Drop" achievements):

Drop marbles from 6" above machine

Drop marbles from 1' above machine

Drop marbles from 2' above machine

Drop marbles from 6' above machine

Systems (not including motor or piston used to charge your pressure vessel):

Use one piston

Use two pistons

Use pneumatics but less than three pistons

Use at least one motor